Cost-Down Opportunities

At GTK, we can implement strategic manufacturing techniques that result in significant cost reductions to our customers.

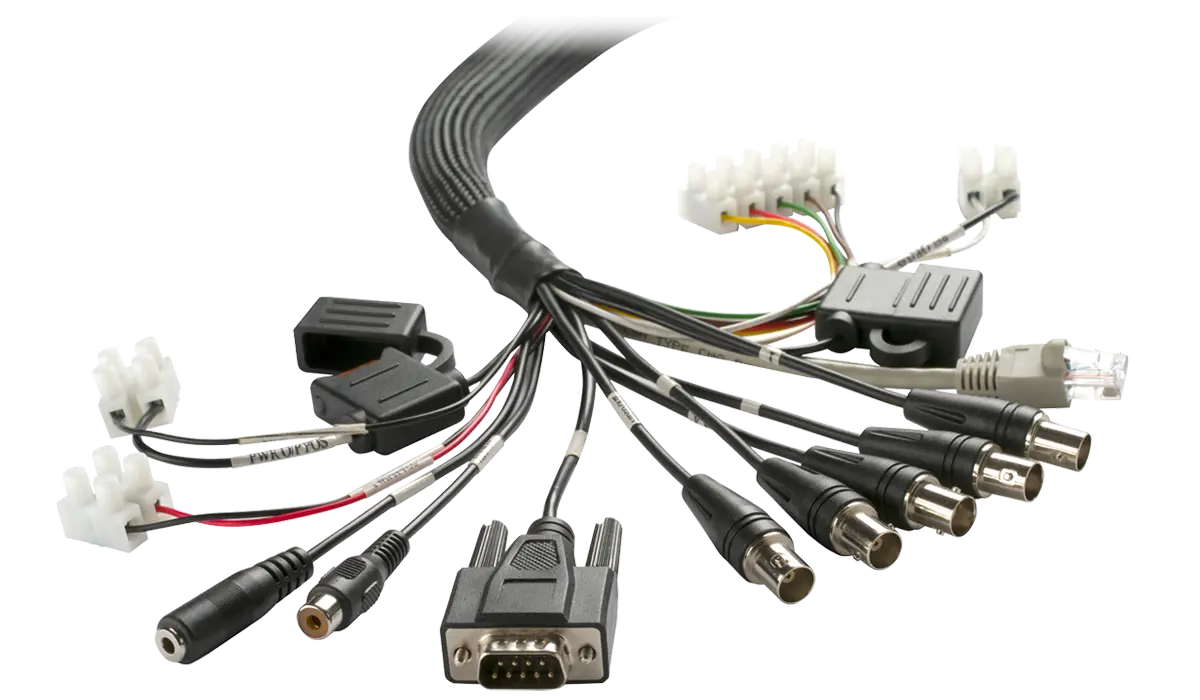

Reducing Build Costs of Cable Assemblies

Before the manufacturing stage, we are able to implement a number of methods to reduce design and build costs. When specifying a connector, for example, we can often suggest alternative manufacturers’ parts. These are all form, fit and function compatible, and fully intermateable with the original manufacturer’s offering.

Other manufacturing cost reduction services are:

- Specifying readily available cable types to minimise MOQs and MOVs

- Design for manufacture (DFM), optimising the cable design to allow for the best manufacturing process

Manufacturing Build Models for Cable Assemblies

We have two manufacturing build models to help our customers when it comes to manufacturing cost reduction. These can be implemented at any stage and are designed to be flexible when fulfilling customers' needs.

Blended Model

This is a combination of different manufacturing locations, where we begin building cable assemblies in either Romania or the Far East before parts are shipped to the UK for completion or the addition of extra components.

Transition Manufacturing

This is about scaling production to meet our customers' demands. We can begin with manufacturing cable assemblies in the UK when volumes are low, then transition to Romania or the Far East as demand increases, maintaining a seamless supply chain throughout.